Dwell period:

Dwell is the stationary period when the heald frames do not change their position and the shade remains open to allow the passage of the shuttle from one shuttle box to the other. In this article, we will discuss the calculation of loom timing.

Timing of loom:

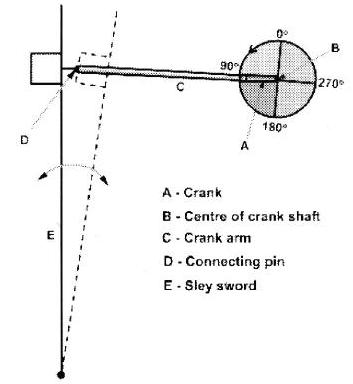

The timing in the loom cycle generally refers to the position of the sley. Timings are described in relation to the angular position of the crankshaft from the reed derive their motion.

Here,

PPM = Pick Per Minute

PPI = Pick Per Inch

RPM = Rotation Per Minute

Calculation of Loom Timing

Problem-1:

Find out the PPM of the loom from the following information:-

- Motor rpm = 950

- Motor pulley dia = 3″

- M/C pulley dia = 8″

- No of tappet = 4

- Counter shaft = 75

- Crank shaft wheel = 74 T (2:03 sp)

Solution:

………PPM

……………………. = Counter shaft

…No of tappet

=> PPM = Counter shaft x No of tappet

=> PPM = 75 x 4

= 300 (ANS)

Problem-2:

Find the production/hour of a loom in which the auxiliary shaft is running at 50 rpm, and there are 4 picks to the round, assume PPI = 40 (3:03sp)

Solution:

……….PPM

……………………. = Counter shaft

…No of tappet

=> PPM = Auxiliary or counter x 4

=> PPM = 50 x 4

=>PPM = 200

……………………………………PPM

Production of Loom = ………………….

……………………………………PPI

……200 x 60

= ……………….. yds /hr

…….40 x 36

= 8.3 yds /hr (ANS)

Problem-3:

Find RPM of bottom shaft, Crank shaft and PPM from data-

- No. of teeth in crank shaft = 48T

- RPM of counter shaft = 75

- Picks to the round = 4

Solution:

……….PPM

…………………….. = Counter shaft

…No of tappet

=> PPM = Auxiliary or counter x 4

=> PPM = 75 x 4

=> PPM = 300 (ANS)

Crank shaft = 300 (ANS)

…………………………300

Bottom Shaft = ………….. = 150 (ANS)

……………………………2