What is Taper Angle of Yarn?

Taper Angle of yarn refers to the angle formed by the surface of a tapered yarn package (such as a cone or cheese) in relation to its axis. In the context of yarn winding, the taper angle is important for determining how the yarn is wound onto the package, impacting the stability and density of the yarn on the spool.

The relation between Taper Angle and Amount of Yarn on a Beam is discussed below:

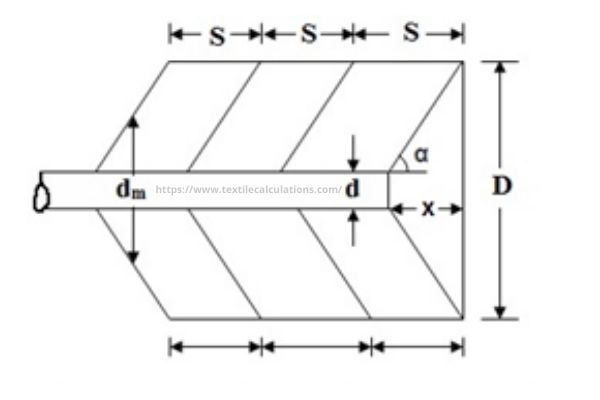

Let,

s = Traverse length.

L = Axial

d = Empty beam dia.

D = Full beam dia.

Relation between Taper Angle and Amount of Yarn on a Beam is:

dm = (D+d)/2 = mean dia.

Where,

X = Tape distance

α = Taper angle

v = Volume of yarn stored on beam.

Let, s > x so as to maintain stability

…….∏D2L ∏d2L

V = ………. – ………….

……….4…………….4

…..∏L

= …….. (D2 – d2)

……4

………….D+d D-d

= ∏L (………) (……….)

…………….2 . 2

From the figure, it is clear that

……….D+d……..D-d

dm = ……… & ………… = x tan α

…………..2………..2

So, v = π L dm (x tanα)

V > π L dm S tan α if, x > s

V < π L dm S tan α if, x < s

So, V ∞ S tan α if α = 90° then V = α

So unlimited amount of yarns can be wound if the flange stays perpendicular to the beam barrel. Practically this is impossible. But this type of package permit’s wind a high amount of yarn.

You may like also: Relation between Yarn Dia and Yarn Count